The Zen Keyboard

Zen is a split ergo keyboard with a few goals in mind:

Be as thin as possible. Other split KBs (Let's Split, Nyquist, Iris) are 13.2mm thick. The Zen is only 8mm thick. You can use whatever feet you chose, I used 1/64” thick rubber sheet to minimize height.

Layout designed for gaming. 1.5u pinky keys, ortho alphas, and angled thumb keys. After trying Ortholiniear, Atreus62, and Ergodox, this is the best layout for gaming and typing. The grid layout of the keys makes positioning over WASD easy. The angled spacebar is a design borrowed from the Ergodox. I have slightly larger hands, and the closer 2u sits perfectly where my thumb rests.

RGB backlighting (not per-key). 16 WS2812b LEDs shine through the perimeter switches. I would have liked to use one per key, but each LED pulls roughly 60mA at max brightness full white. 62 Keys x 60mA = 3.72A, way over normal USB spec. The current setup of 32 total LEDs pulls the voltage so low at max that the arduino turns off. I like using GMK or blank keycaps, so individual shine-through legends aren't necessary. The perimeter lighting still lights up the majority of the switches, and QMK's default animations work well with the setup.

Reduce cost by using PCBs for the base and top layers. No screws, standoffs, or laser cut acrylic/steel. FR4 provides rigidity and allows me to customize the look of the keyboard with graphics. All boards can be ordered from the same source.

Keycaps are completely compatible with ergodox keysets. The 1st column allows for 1u or 1.5u keycaps.

A History

In 2017, I finally learned to touch-type with my Atreus62. I loved to type on that keyboard but didn't like to game on it because my hand would get cramped by the layout. As it moved to the office permanently, I began to look for an ortholinear keyboard to use at home for typing and gaming. I settled on the XD75RE. While the grid layout worked for the alphas, my pinkies were cramped and I didn't like the 1u spacebar. I began 3D printing prototype layouts based off of the Ergodox. The last 3D printed prototype was hand-wired with an Arduino Pro Micro. Once I had settled on a layout and tried it for a week, I designed and had plates made out of carbon fiber. Unfortunately, the waterjet house I had make the plates could got get their drill holes to work properly in carbon fiber. I wanted to learn PCB design, so I decided to design the keyboard myself.

Inspired by projects like Lets\_Split, I had to learn the process behind PCB design. The boards are completely reversible, so every component on the board has to be replicated on the other side of the board. For through-hole components this is easy, but I had to use SMD componenets to reduce size. The RGB LEDs on the bottom board proved to be the most difficult components to wire. I used one side as a 5V plane and the other as a ground plane, and oriented all of the pads in the same direction to make soldering easier. The data in, data out, 5V, and Ground pads all had to be wired to the Arduino and to the other side of the board through many, many vias. At the time of designing the keyboard, I didn't know how to tie schematic components to board footprints, so I had to "fly blind" and visually confirm that my traces were correct. After ordering the 5 prototype PCBs, I found that they all worked except for one small trace that could be replaced easily.

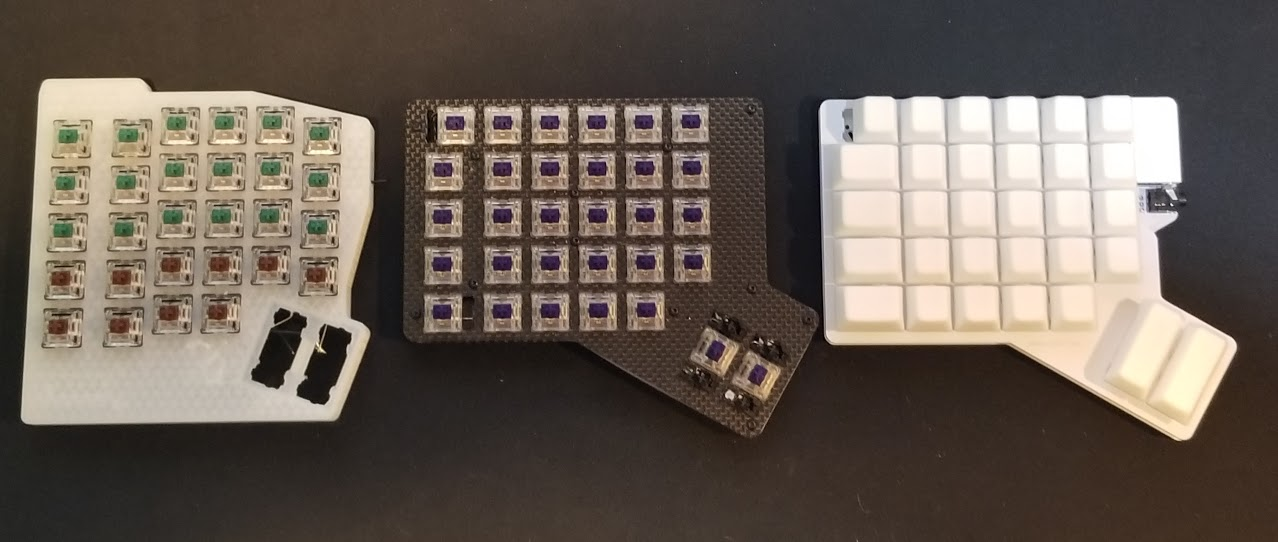

Below from left to right is the 3D printed prototype, the carbon-fiber cut keyboard, and finally the first Zen production-ready board.